Shipping containers

Shipping containers are versatile, robust, and essential components of the global logistics infrastructure, facilitating the efficient movement of goods across continents and oceans. In a world where creativity knows no bounds, shipping containers stand as giants ready to shape-shift into whatever you envision. At BoxbayContainer, we celebrate the boundless possibilities of these steel behemoths, transforming them into extraordinary spaces that redefine the concept of architecture. Depending on their intended use, some shipping containers may feature ventilation systems to control airflow and prevent condensation buildup. Insulation materials may also be added to regulate temperature and protect sensitive cargo from extreme heat or cold.

Shipping containers can be modified to suit various purposes beyond transportation. Common modifications include adding windows, doors, partitions, insulation, electrical wiring, plumbing, and interior finishes to create living spaces, offices, retail shops, and more. They are typically manufactured in compliance with international standards set by organizations such as the International Organization for Standardization (ISO). They undergo rigorous testing and certification processes to ensure quality, safety, and compatibility with global transportation networks.

Material and Construction:

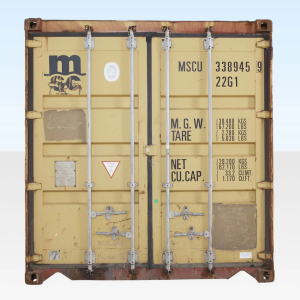

- Steel Construction: Shipping containers are predominantly made of steel, providing durability and structural integrity.

- Corrugated Walls: The walls of shipping containers are typically corrugated for added strength, allowing them to withstand stacking and transportation stresses.

- Corner Castings: Each corner of the container is reinforced with steel castings, allowing for secure stacking and lifting using cranes or forklifts.

- Flooring: The floor of a shipping container is typically made of marine-grade plywood or steel, designed to support heavy loads and resist corrosion.

Dimensions:

Shipping containers come in various sizes, with the most common being 20 feet and 40 feet in length. Standard widths are typically 8 feet, and heights are usually 8.5 feet. However, high cube containers offer extra height, typically 9.5 feet.

- 20-foot Standard Container (20′ x 8′ x 8.5′): This container has a length of 20 feet, a width of 8 feet, and a height of 8.5 feet. It’s one of the most widely used sizes and is suitable for transporting general cargo.

- 40-foot Standard Container (40′ x 8′ x 8.5′): This container doubles the length of the 20-foot standard container while maintaining the same width and height. It provides more space for larger loads or bulky items.

- 40-foot High Cube Container (40′ x 8′ x 9.5′): Similar to the standard 40-foot container, the high cube version has extra height, measuring 9.5 feet tall instead of 8.5 feet. This additional vertical space is advantageous for transporting tall items or maximizing storage capacity.

- 10-foot Container (10′ x 8′ x 8.5′): A smaller option compared to the standard sizes, the 10-foot container is suitable for transporting smaller loads or for use in limited spaces where larger containers cannot fit.

- 45-foot Container (45′ x 8′ x 9.5′): This container is less common but offers extra length compared to the standard 40-foot container. It provides additional space for cargo while still maintaining the height advantage of the high cube design.

- Specialized Containers: In addition to the standard sizes mentioned above, there are specialized containers designed for specific purposes. These include refrigerated containers (reefers) for transporting perishable goods, open-top containers for oversized cargo, flat rack containers for transporting heavy machinery or vehicles, and tank containers for transporting liquids or gases.

These are some of the most common dimensions of shipping containers, but variations exist to meet specific requirements and accommodate different types of cargo.

Shipping Containers

Shipping Containers

Shipping Containers

Shipping Containers

Shipping Containers

Shipping Containers

Shipping Containers